ThermoPlastics

Thermoplastics are polymers that can be softened or melted when heated to a specific temperature. When combined with rapid production processes, Tenax™ ThermoPlastics allow for fast processing, low scrap rates as well as high mechanical performance, chemical resistance and recyclability. Teijin currently offers three types of Tenax™ ThermoPlastics: ThermoPlastic UniDirectional (TPUD), ThermoPlastic Consolidated Laminate (TPCL) and ThermoPlastic Woven Fabric (TPWF).

Tenax™ ThermoPlastic UniDirectional (TPUD)

This thermoplastic unidirectional prepreg combines carbon fiber with a tailored sizing for thermoplastic applications and a high-temperature polymer, such as for PEEK, PPS, LM and PAEK. It is available in standard widths (304.8 mm and 609.6 mm) and with slitting on demand (down to 3.175 mm).

Tenax™ ThermoPlastic Consolidated Laminate (TPCL)

These are consolidated laminate sheets made of several layers of carbon woven fabric coated with a thermoplastic polymer. They are based on Tenax™ Carbon Fiber and high-temperature polymer matrix systems to provide superior mechanical, chemical and thermal properties.

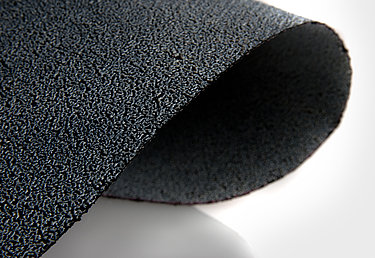

Tenax™ ThermoPlastic Woven Fabric (TPWF)

This is a woven fabric coated with a thermoplastic polymer. It is based on Tenax™ Carbon Fiber and a high-temperature polymer matrix system to provide superior mechanical, chemical and thermal properties.