Weaving

Carbon fiber can be processed as a woven fabric. The method of weaving has a significant influence on the carbon fiber’s appearance and properties, including its strength and drapeability. Carbon fiber weaving must be done with the appropriate tension, with conventional 2D fabrics weaved with at least two yarn systems crossing at right angles. Teijin has honed the carbon fiber weaving process over many years.

Tenax™ carbon fiber weaving process

The yarn systems running in the direction of production are called warp yarns, while the yarn systems running transversely are the weft yarns. The warp/weft interlacing results in the formation of the carbon fiber fabric. During the weaving process, the warp and weft yarns are closely controlled and monitored by computers, ensuring the right tension and strength is achieved for each weave.

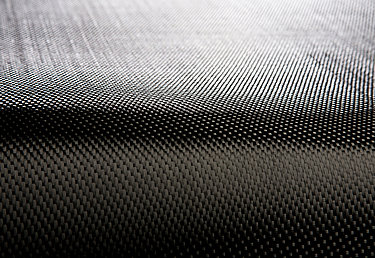

Tenax™ carbon fiber weave patterns

The three basic weave patterns are plain, twill, and satin. A plain weave looks symmetrical, with the tows woven in an over/under pattern, for a checkerboard finish. A twill weave has an over/under pattern that creates a diagonal finish. A satin weave is a method adapted from making silk fabrics, in order to achieve a smooth carbon fiber finish.