Civil Engineering

Tenax™ carbon fiber drives innovation in construction and civil engineering

Carbon fiber can be used in a wide range of construction applications due to its high strength and flexibility. This includes refurbishing existing structures, such as roads and bridges, and reinforcing entirely new structures. Tenax™ carbon fiber is driving innovation in the construction industry. Its conductivity makes it an integral material for smart buildings, conducting heat and energy, transmitting information about a building’s parameters, and shielding electromagnetic interference. Teijin is a leader in carbon fiber technology and we look forward to what the future holds in construction with this innovative material.

Reinforcing carbon concrete with Tenax™ carbon fiber

Carbon fiber is a non-corroding material, enabling concrete layers to be much thinner, as there is no steel core to protect from corrosion. Carbon concrete leads to a reduction in the amount of concrete used in buildings, with side benefits like lower logistic costs and shorter construction and drying times. Together with the CARBOrefit® consortium, we are continuing to innovate in the area of carbon concrete.

Carbon fiber applications in civil engineering

All Products

Tenax™ Filament Yarn and Tenax™ Short Fibers are key products for civil engineering. Carbon fiber laminates improve the mechanical properties of ceilings and columns, while carbon fiber used in the reinforcement of new buildings is a viable alternative to steel-reinforced precast elements, as they have better resistance to earthquake damage and corrosion. A new and fast-growing option is refurbishment with carbon fiber grid structures that can be applied with shotcrete.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the construction industry, but also on the future of the planet. Using carbon fiber in buildings and constructions requires less materials and lasts longer, providing a sustainable and viable alternative to previous methods and materials used in civil engineering.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn provides high tensile strength to support building and engineering structures, by increasing stableness, reducing weight, and preventing cracks. The corrosion resistance of carbon fiber increases the lifetime of concrete structures while providing a more sustainable way to build new structures and repair old ones. Tenax™ Filament Yarn can also be used in construction machinery and components, including as pipes, rolls, and robot arms.

Used Products :

Tenax™ Short Fibers

In the construction industry, Tenax™ Short Fibers increase the conductivity of industrial paints and coatings, while enhancing the heat distribution. Additionally, carbon fiber's corrosion resistance, property shielding, and non-burning are highly beneficial for paints and coatings.

Used Products :

Carbon Grid

Weaved grids made from Tenax™ Carbon Fiber are used to reinforce concrete and asphalt. They are lighter than steel and subject to far less corrosion over time. They can also be placed closer to the surface, for a thinner construction.

Used Products :

CARBOrefit® Carbon-reinforced Concrete

Carbon concrete is corrosion resistant, with a thin cover resulting in less concrete being used. It provides strengthening, crack reduction, and durability, while being a sustainable reinforcement solution.

Used Products :

Wraps

Tenax™ Carbon Fiber used in wraps provides structural and seismic strengthening, increasing load-bearing capacity and reducing corrosion and cracking.

Used Products :

Flooring

Tenax™ Carbon Fiber used for flooring provides electrical conductivity and electrostatic dispersion, for enhanced resilience, also in flame retardant coatings.

Used Products :

Rebars

Rebars made from Tenax™ Carbon Fiber have a higher tensile strength, compared to steel, and also last longer, due to corrosion resistance. Carbon fiber rebars can be used for balconies, with faster installation and increased load bearing.

Used Products :

Rebars

Rebars made from Tenax™ Carbon Fiber have a higher tensile strength, compared to steel, and also last longer, due to corrosion resistance.

Used Products :

CARBOrefit® Carbon-reinforced Concrete

Carbon concrete is corrosion resistant, with a thin cover resulting in less concrete being used. It provides strengthening, crack reduction, and durability, while being a sustainable reinforcement solution.

Used Products :

Carbon Wraps

Tenax™ Carbon Fiber used in wraps provides structural and seismic strengthening, increasing load-bearing capacity and reducing corrosion and cracking.

Used Products :

Prefabricated parts with carbon grid reinforcement

Prefabricated parts with carbon fiber grid reinforcement provide corrosion resistance and high strength, resulting in significant material savings on concrete and materials. The lightweight parts offer further advantages in terms of manufacturing, transportation, and installation.

Used Products :

Laminate Strips and shear links

Pultruded carbon fiber laminates increase the bearing capacity of the building, while reducing long-term structural deformation. The laminates improve structural rigidity (for bending strength and shear strength), and provide a material for the repair of impact damage and fatigue.

Used Products :

Winding ropes

Cable winding and lift ropes made from Tenax™ Carbon Fiber offer high material resistance, low maintenance, minor dead weight, and increased travel heights.

Used Products :

Curtain wall panels

Curtain wall panels with carbon grids or sandwich elements are optimized for modern building construction, providing corrosion resistance and the ability for electrical conductivity via the fibers.

Used Products :

Profiles

Pultruded carbon profiles for large-scale glass elements combine a high load capacity with a minor dead weight. They offer a high resilience to sun exposure and low thermal expansion.

Used Products :

All Products

Tenax™ Filament Yarn and Tenax™ Short Fibers are key products for civil engineering. Carbon fiber laminates improve the mechanical properties of ceilings and columns, while carbon fiber used in the reinforcement of new buildings is a viable alternative to steel-reinforced precast elements, as they have better resistance to earthquake damage and corrosion. A new and fast-growing option is refurbishment with carbon fiber grid structures that can be applied with shotcrete.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the construction industry, but also on the future of the planet. Using carbon fiber in buildings and constructions requires less materials and lasts longer, providing a sustainable and viable alternative to previous methods and materials used in civil engineering.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn provides high tensile strength to support building and engineering structures, by increasing stableness, reducing weight, and preventing cracks. The corrosion resistance of carbon fiber increases the lifetime of concrete structures while providing a more sustainable way to build new structures and repair old ones. Tenax™ Filament Yarn can also be used in construction machinery and components, including as pipes, rolls, and robot arms.

Used Products :

Tenax™ Short Fibers

In the construction industry, Tenax™ Short Fibers increase the conductivity of industrial paints and coatings, while enhancing the heat distribution. Additionally, carbon fiber's corrosion resistance, property shielding, and non-burning are highly beneficial for paints and coatings.

Used Products :

Carbon Wraps

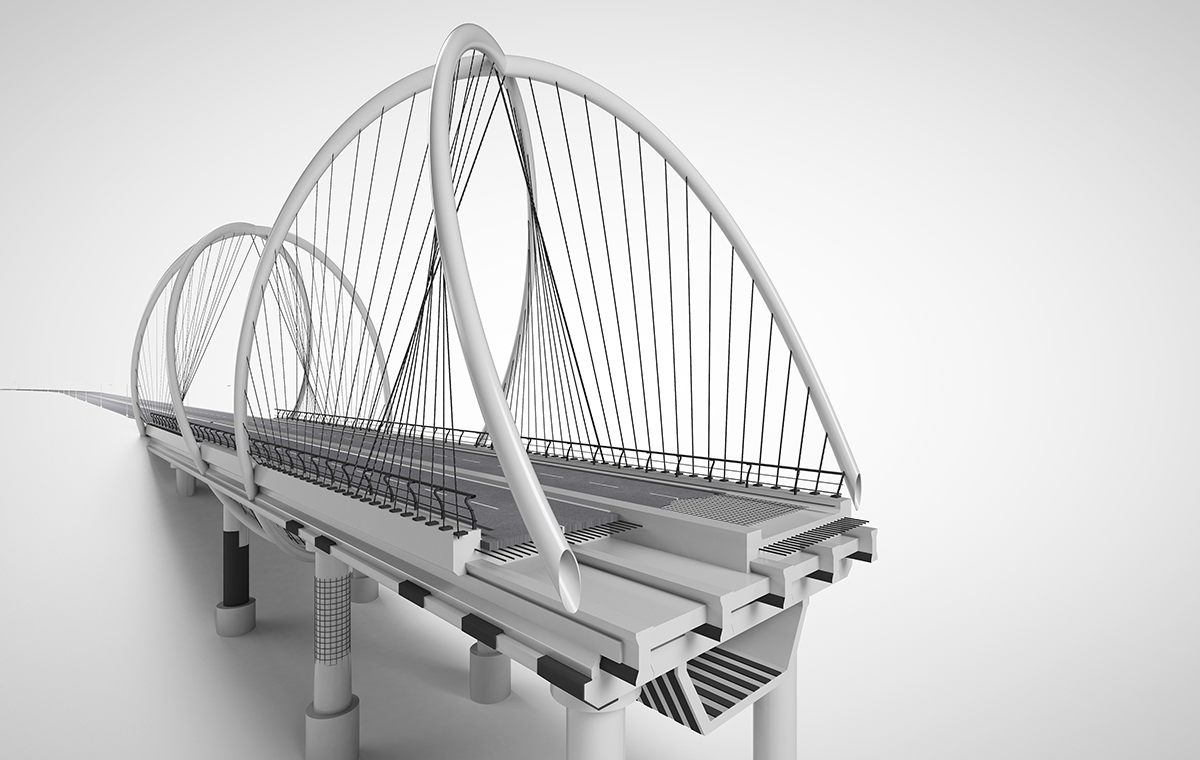

Tenax™ Carbon Fiber used in wraps provides structural and seismic strengthening, for new and retrofitted bridges, increasing load-bearing capacity and reducing corrosion and cracking.

Used Products :

CARBOrefit® Carbon Concrete

Carbon concrete is corrosion resistant, with a thin cover resulting in less concrete being used. It provides strengthening, crack reduction, and durability, while being a sustainable reinforcement solution.

Used Products :

Laminate strips and shear links

Pultruded carbon fiber laminates increase the bearing capacity of a bridge, while reducing long-term structural deformation. The laminates improve structural rigidity (for bending strength and shear strength), enable increased traffic loads, and provide a material for the repair of impact damage and fatigue.

Used Products :

Rebars

Rebars made from Tenax™ carbon fiber have a higher tensile strength, compared to steel, and also last longer, due to corrosion resistance.

Used Products :

Cables

Arch, suspension and stay cables made from Tenax™ carbon fiber provide high fatigue strength, light weight, and corrosion resistance. They are especially suitable for bridges with high traffic loads and in corrosive envirornments, such as near oceans and seas.

Used Products :

Carbon Grid

Weaved grids made from Tenax™ carbon fiber are used to reinforce concrete and asphalt. They are lighter than steel and subject to far less corrosion over time. They can also be placed closer to the surface, for a thinner construction of pavements, roads, and walkways.

Used Products :

Laminate Strips and shear links

Pultruded carbon fiber laminates increase the bearing capacity of the bridge, while reducing long-term structural deformation. The laminates improve structural rigidity (for bending strength and shear strength), enable increased traffic loads, and provide a material for the repair of impact damage and fatigue.

Used Products :

All Products

Tenax™ Filament Yarn and Tenax™ Short Fibers are key products for civil engineering. Carbon fiber laminates improve the mechanical properties of ceilings and columns, while carbon fiber used in the reinforcement of new buildings is a viable alternative to steel-reinforced precast elements, as they have better resistance to earthquake damage and corrosion. A new and fast-growing option is refurbishment with carbon fiber grid structures that can be applied with shotcrete.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the construction industry, but also on the future of the planet. Using carbon fiber in buildings and constructions requires less materials and lasts longer, providing a sustainable and viable alternative to previous methods and materials used in civil engineering.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn provides high tensile strength to support building and engineering structures, by increasing stableness, reducing weight, and preventing cracks. The corrosion resistance of carbon fiber increases the lifetime of concrete structures while providing a more sustainable way to build new structures and repair old ones. Tenax™ Filament Yarn can also be used in construction machinery and components, including as pipes, rolls, and robot arms.

Used Products :

Tenax™ Short Fibers

In the construction industry, Tenax™ Short Fibers increase the conductivity of industrial paints and coatings, while enhancing the heat distribution. Additionally, carbon fiber's corrosion resistance, property shielding, and non-burning are highly beneficial for paints and coatings.

Used Products :

Transport

Prefabricated parts made of carbon concrete are thinner and lighter, resulting in increased efficiencies in transportation and logistics, as more parts can be delivered in one truck.

Used Products :

Precast carbon concrete parts

Precast parts made of carbon concrete are corrosion resistant, providing more durability and requiring less maintenance. Their high strength enables lean design and long-term material savings.

Used Products :

Handling on building site

Thin and light precast parts made of carbon concrete enable easier installation and faster building times. Their light weight also means using smaller cranes on construction sites.

Used Products :

Holding bars for crawler cranes

Carbon fiber holding bars and lashing points for mobile cranes are lightweight, high strength and wear-free. They provide longer boom combinations and fast assembly/disassembly of the crane.

Used Products :

Carbon Wraps

Tenax™ carbon fiber used in wraps provides structural and seismic strengthening, increasing load-bearing capacity and reducing corrosion and cracking.

Used Products :

Laminate strips and shear links

Pultruded carbon fiber laminates increase the bearing capacity of the building, while reducing long-term structural deformation. The laminates improve structural rigidity (for bending strength and shear strength), and provide a material for the repair of impact damage and fatigue.

Used Products :

Cathodic protection

Carbon grids are used for cathodic protection of steel reinforcements, offering electrical conductivity and helping to prevent the steel from corroding.

Used Products :

CARBOrefit® Carbon-reinforced Concrete

Carbon concrete is corrosion resistant, with a thin cover resulting in less concrete being used. It provides strengthening, crack reduction, and durability, while being a sustainable reinforcement solution.

Used Products :

Carbon Grid

Weaved grids made from Tenax™ carbon fiber are used to reinforce concrete and asphalt. They are lighter than steel and subject to far less corrosion over time. They can also be placed closer to the surface, for a thinner construction of pavements, roads, and walkways.

Used Products :

Carbon Wraps

Tenax™ carbon fiber used in wraps provides structural and seismic strengthening, increasing load-bearing capacity and reducing corrosion and cracking.

Used Products :

All Products

Tenax™ Filament Yarn and Tenax™ Short Fibers are key products for civil engineering. Carbon fiber laminates improve the mechanical properties of ceilings and columns, while carbon fiber used in the reinforcement of new buildings is a viable alternative to steel-reinforced precast elements, as they have better resistance to earthquake damage and corrosion. A new and fast-growing option is refurbishment with carbon fiber grid structures that can be applied with shotcrete.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the construction industry, but also on the future of the planet. Using carbon fiber in buildings and constructions requires less materials and lasts longer, providing a sustainable and viable alternative to previous methods and materials used in civil engineering.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn provides high tensile strength to support building and engineering structures, by increasing stableness, reducing weight, and preventing cracks. The corrosion resistance of carbon fiber increases the lifetime of concrete structures while providing a more sustainable way to build new structures and repair old ones. Tenax™ Filament Yarn can also be used in construction machinery and components, including as pipes, rolls, and robot arms.

Used Products :

Tenax™ Short Fibers

In the construction industry, Tenax™ Short Fibers increase the conductivity of industrial paints and coatings, while enhancing the heat distribution. Additionally, carbon fiber's corrosion resistance, property shielding, and non-burning are highly beneficial for paints and coatings.

Used Products :

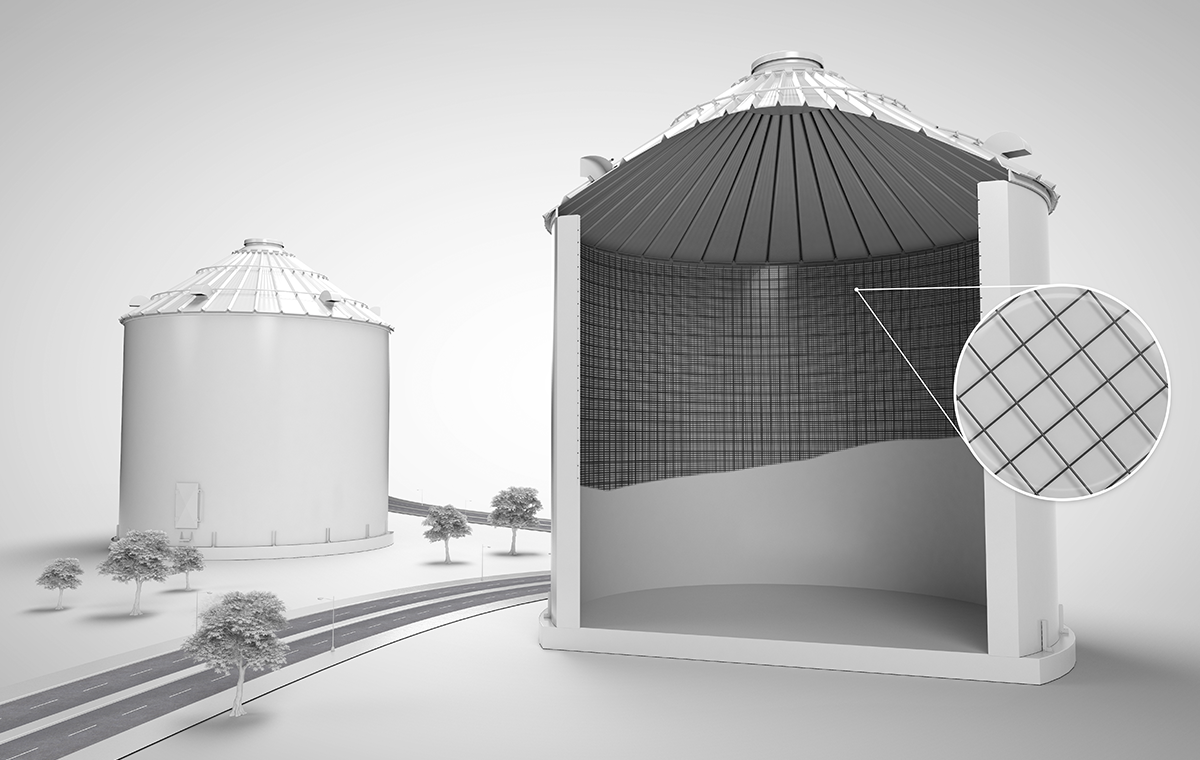

CARBOrefit® Carbon-reinforced Concrete

Carbon concrete is corrosion resistant, with a thin cover resulting in less concrete being used. It provides strengthening, crack reduction, and durability, while being a sustainable reinforcement solution. Rollable carbon grids are especially convenient for the restoration of concrete silos. The thin concrete cover saves volume inside the silo, while material savings enable fast execution and refill of the silo.

Used Products :

Carbon Grid

Weaved grids made from Tenax™ carbon fiber are used to reinforce concrete and asphalt. They are lighter than steel and subject to far less corrosion over time. They can also be placed closer to the surface, for a thinner construction.