Automotive

Tenax™ Carbon Fiber is revolutionizing the automotive industry

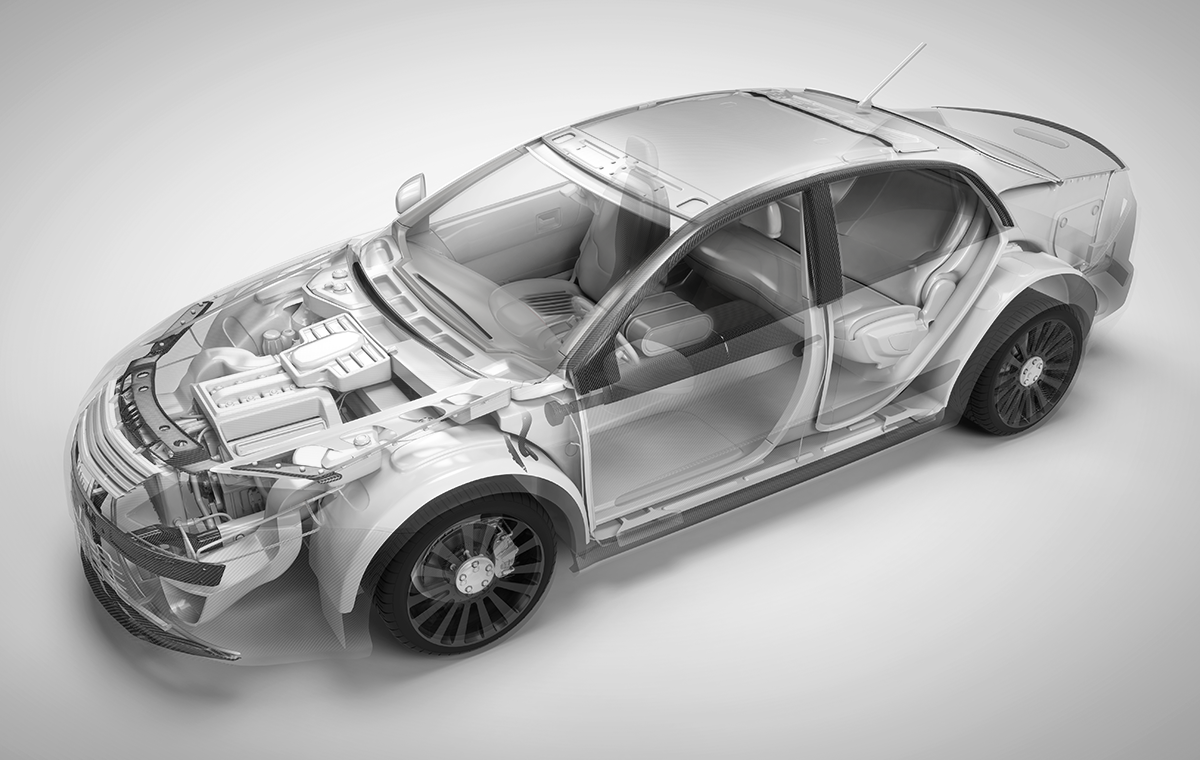

The increasing use of carbon fiber in the automotive industry is enabling manufacturers to develop innovations that make vehicles more efficient by reducing weight and safer and more comfortable by increasing rigidity and strength. Improving efficiency results in reduced CO2 emissions. Carbon fiber can also be recycled and reused, making it more sustainable.

Tenax™ Carbon Fiber is used in all types of vehicles

Carbon fiber composites are technologically advanced chemical formulations that offer a number of significant advantages over steel and aluminum, especially in the automotive industry. Tenax™ Carbon Fiber products are used in many automotive applications, including family vehicles, high-performance racing cars, and electric and hybrid vehicles.

Carbon fiber applications on automotive

All Products

Tenax™ Carbon Fiber enables automotive manufacturers to take a new approach to vehicle design, with lightweight vehicles that are more energy efficient. Weight reductions can result in significant energy and emissions savings over the lifetime of the vehicle. The transition to electric vehicles will see an increasing use of carbon fiber, already an important material for battery housings, as it can be formulated to be flame resistant and self-extinguishing.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the automotive industry, but also on the future of the planet. Lighter vehicles with reduced energy consumption help to significantly reduce emissions.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn has a high tensile strength and modulus, making it ideal for producing the next generation of lightweight materials for the automotive industry. The yarn offers optimal weight reduction while meeting all necessary mechanical and surface requirements.

Used Products :

Tenax™ Short Fibers

Tenax™ Short Fibers improve the material properties in thermoset and thermoplastic applications, and are often used as seals in the automotive industry. Short fibers increase abrasion resistance and enhance compressive strength, while the easy-to-use bundle sizes improve handling and production.

Used Products :

Tenax™ ThermoPlastics

Tenax™ ThermoPlastics are highly suitable for automotive body parts and structural components, as the composite can be easily heated and molded multiple times during processing. Further advantages include low yield stress during molding, material homogeneity in complex part design, greater flexibility in molding and lower tooling costs.

Used Products :

Tenax™ Dry Reinforcements

Tenax™ Dry Reinforcements provide flexibility in component design and offer the potential for complex shapes. Dry reinforced materials enable the manufacturing of high quality carbon fiber reinforced components, for a range of products specifically designed for automotive applications.

Used Products :

Tenax™ ThermoSets

Tenax™ ThermoSets provide significant weight savings over steel and aluminum while reducing tooling costs and improving design flexibility, making them ideal for automotive applications.

Used Products :

Pyromex™

Pyromex™ meets flame resistance requirements while fulfilling environment regulations. It does not melt, drip or develop into flames. In the automotive industry, it is ideal for use in applications requiring fire protection and resistance, such as in the engine compartment trim.

Used Products :

Front- and Rear spoiler

Lightweight carbon fiber spoilers offer high stiffness and strength, and are ideal for motorsport applications. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements are used for spoilers that reduce drag and downforce. The class A surfaces also deliver the visual aesthetics required for vehicles.

Used Products :

Engine hood

Engine hoods made of carbon fiber help make vehicles more efficient, with the surface layers optimized for energy and impact absorption, enhancing safety. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements enable lightweight hood construction, with class A surfaces for visual aesthetics.

Used Products :

Roof

Vehicle roofs made of carbon fiber provide high stiffness and reduce the energy consumption of the vehicle. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements enable lightweight roof construction, with class A surfaces for visual aesthetics.

Used Products :

Trunk lid frame

Trunk lid frames made of carbon fiber are lightweight with high stiffness. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements enable high-performance lid frames that help make vehicles more energy efficient. The class A surfaces also deliver the visual aesthetics required for vehicles.

Used Products :

Door or door component

Doors and door components made of carbon fiber are designed for high energy absorption, to improve occupant safety. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements are used for lightweight doors and components with optimized design options. The class A surfaces deliver the visual aesthetics required for vehicles.

Used Products :

Wheel rim

Carbon fiber wheel rims improve driving dynamics and reduce noise. With light weight, high stiffness, and high strength, the rims provide better acceleration and deceleration, while enabling more flexibility in design. Tenax™ ThermoSets based on Tenax™ Filament Yarn and Tenax™ Dry Reinforcements are used for rims that result in reductions in unsprung weight. The optional class A surfaces provide outstanding visual aesthetics for wheel rims.

Used Products :

All Products

Tenax™ Carbon Fiber enables automotive manufacturers to take a new approach to vehicle design, with lightweight vehicles that are more energy efficient. Weight reductions can result in significant energy and emissions savings over the lifetime of the vehicle. The transition to electric vehicles will see an increasing use of carbon fiber, already an important material for battery housings, as it can be formulated to be flame resistant and self-extinguishing.

Sustainable carbon fiber production and recycling

Teijin is innovating in carbon fiber not only with the focus on the future of the automotive industry, but also on the future of the planet. Lighter vehicles with reduced energy consumption help to significantly reduce emissions, while recyclable carbon fiber prepares current vehicles for more recycling in the future, reducing waste.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn has a high tensile strength and modulus, making it ideal for producing the next generation of lightweight materials for the automotive industry. The yarn offers optimal weight reduction while meeting all necessary mechanical and surface requirements.

Used Products :

Tenax™ Short Fibers

Tenax™ Short Fibers improve the material properties in thermoset and thermoplastic applications, and are often used as seals in the automotive industry. Short fibers increase abrasion resistance and enhance compressive strength, while the easy-to-use bundle sizes improve handling and production.

Used Products :

Tenax™ ThermoPlastics

Tenax™ ThermoPlastics are highly suitable for automotive body parts and structural components, as the composite can be easily heated and molded multiple times during processing. Further advantages include low yield stress during molding, material homogeneity in complex part design, greater flexibility in molding, and lower tooling costs.

Used Products :

Tenax™ Dry Reinforcements

Tenax™ Dry Reinforcements provide flexibility in component design and offer the potential for complex shapes. Dry reinforced materials enable the manufacturing of high quality carbon fiber reinforced components, for a range of products specifically designed for automotive applications.

Used Products :

Tenax™ ThermoSets

Tenax™ ThermoSets provide significant weight savings over steel and aluminum while reducing tooling costs and improving design flexibility, making them ideal for automotive applications.

Used Products :

Pyromex™

Pyromex™ meets flame resistance requirements while fulfilling environment regulations. It does not melt, drip or develop into flames. In the automotive industry, it is ideal for use in applications requiring fire protection and resistance, such as in the engine compartment trim.

Used Products :

Crash structures

Carbon fiber tests extremely well in crash and impact scenarios, with high energy absorption and rigid strength. Tenax™ ThermoSets or Tenax™ ThermoPlastics can be used in crash structures to enhance safety for occupants.

Used Products :

Strut Bar / Dom strut

Lightweight and stiff carbon fiber strut bars connect the strut towers to provide more rigidity to the vehicle, at the front and rear. Strut bars made of braided or winded Tenax™ Filament Yarn or Tenax™ TPUD Slit Tape also help to improve the handling of the vehicle.

Used Products :

Rotor Bandages of electrical motors

Carbon fiber rotor bandages are strong and lightweight, helping to make electric motors more efficient. Tenax™ ThermoSets or Tenax™ ThermoPlastics minimizes the expansion of the outer rotor diameter, enabling more compact design and reducing the air gap between the rotor and the stator.

Used Products :

Engine cover

Carbon fiber engine covers give the vehicle a premium, sporty look. Fire and flame resistant Pyromex™ is ideal for this application, while also meeting environmental and safety requirements.

Used Products :

Brake disc / Friction plate

Brake discs and friction plates made of Tenax™ Carbon Fiber, with reinforced ceramics, provide high performance on dry and wet surfaces, with added benefits in terms of weight, corrosion resistance, durability, handling and appearance.

Used Products :

Foot pedals

Carbon fiber foot pedals enhance comfort and control when driving, while also providing weight advantages. Composite materials reinforced with short or milled Tenax™ Carbon Fiber, added during injection and overmoulding processes, look great in the vehicle, giving it a racing-car feel.

Used Products :

Seat heating

For seat heating applications, carbon fiber has the benefit of heating rapidly and flexing under heavy loads. Composite materials reinforced with Tenax™ Short or Milled Carbon Fibers, added during injection and overmoulding processes, make lightweight, durable and reliable parts for seat heating.

Used Products :

Seat shell

Carbon fiber seat shells combine structural load and energy-absorbing strength with a lightweight construction. Tenax™ Carbon Fiber Filament Yarns have a ratio of electrical conduction and resistance properties suitable to create heat via electricity within the seat shell.

Used Products :

Drive shafts

A carbon fiber drive shaft is lightweight, rigid and durable, delivering more engine power to the wheels with a lower spring rate. Drive shafts can be made of filament winding from Tenax™ Filament Yarn or Tenax™ ThermoSet Towpregs. Winding is a more efficient process, with higher output and less waste. Carbon fiber also helps to reduce noise, vibration and harshness.

Used Products :

Battery enclosures

Carbon fiber battery enclosures are lightweight, stable and safe. They require less space, enabling the enclosures to be designed in more efficient shapes with a higher packing density. The enclosures combine unidirectional or multidirectional carbon fiber forms with traditional, randomly oriented chopped rovings.

Used Products :

Pillars (A, B, C) or pillar reinforcement

Carbon fiber tests extremely well in crash and impact scenarios, with high energy absorption and rigid strength. Tenax™ ThermoSets can be used in the A, B, and C pillars and in pillar reinforcement to enhance safety for occupants.

Used Products :

Door sill

Door sill protectors made from Tenax™ Carbon Fiber reinforced with Tenax™ ThermoSets are weaved into strips that can be placed on the vehicle’s door sill with adhesive. The class A surfaces deliver the visual aesthetics required for vehicle interiors.

Used Products :

Seals

Tenax™ Milled Carbon Fibers can be used in seals to significantly increase abrasion resistance, while improving the compressive strength.