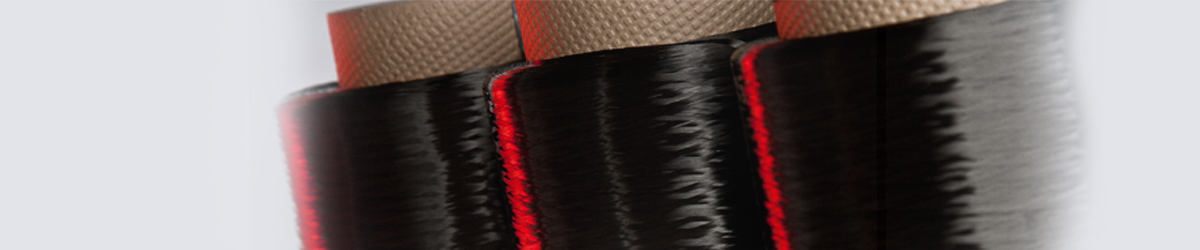

Filament Yarn

Tenax™ Filament Yarn is a high-performance carbon fiber product that significantly enhances and strengthens the properties of thermoset and thermoplastic composites. This includes products made for aerospace, automotive and several industrial applications. With a high tensile strength and tensile modulus, Tenax™ Filament Yarn is ideally suited for many processes, such as prepregging, filament winding, pultrusion, weaving and braiding. The yarn is available in qualities ranging from 67 to 3,200 tex or 1,000 to 48,000 filaments.

The benefits of carbon fiber sizing

The application of a thin coating to the surface, known as fiber sizing, protects Tenax™ Filament Yarn during handling, processing, compounding, and composite processing, while improving wet-out. A wide range of available sizings make Tenax™ Filament Yarn fully compatible with thermoset matrix systems, including epoxy, polyurethane and vinylester. Teijin also offers products with tailored thermoplastic sizing compatible with thermoplastic matrix systems, such as PEEK, PEI and PA.

Tensile properties

Properties of TenaxTM Filament Yarn

Please choose

Please choose

| Grade | Filament count | Yield | Tensile Strength | Tensile Modulus | Elongation | Density |

|---|---|---|---|---|---|---|

| tex | MPa | GPa | % | g/cm3 | ||

| Standard Modulus | ||||||

| HTA40 | 1 000 | 67 | 4100 | 240 | 1.7 | 1.77 |

| 3 000 | 200 | |||||

| 6 000 | 400 | |||||

| 12 000 | 800 | |||||

| HTS40 | 3 000 | 200 | 4400 | 240 | 1.8 | 1.77 |

| 6 000 | 400 | |||||

| 12 000 | 800 | |||||

| 24 000 | 1600 | |||||

| HTS45 | 3 000 | 200 | 4500 | 245 | 1.8 | 1.76 |

| 12 000 | 800 | 240 | 1.9 | 1.77 | ||

| STS40 | 24 000 (PU) | 1600 | 4300 | 240 | 1.8 | 1.78 |

| 24 000 (EP) | 1600 | 250 | 1.7 | 1.78 | ||

| 48 000 | 3200 | 250 | 1.7 | 1.77 | ||

| UTS50 | 12 000 | 800 | 5100 | 245 | 2.1 | 1.78 |

| 24 000 | 1630 | |||||

| ITS50 | 24 000 | 1630 | 5100 | 265 | 1.9 | 1.80 |

| ITS55 | 24 000 | 1600 | 5100 | 280 | 1.8 | 1.75 |

| Intermediate Modulus | ||||||

| IMS40 | 3 000 | 170 | 4500 | 290 | 1.6 | 1.73 |

| 6 000 | 340 | |||||

| 12 000 | 680 | |||||

| IMS60 | 6 000 | 210 | 5800 | 290 | 2.0 | 1.79 |

| 12 000 | 410 | |||||

| 24 000 | 830 | |||||

| IMS65 | 24 000 | 830 | 6000 | 290 | 2.1 | 1.78 |

| High Modulus | ||||||

| HMA35 | 12 000 | 760 | 3300 | 355 | 0.9 | 1.78 |

| UMS40 | 12 000 | 390 | 4700 | 390 | 1.2 | 1.79 |

| 24 000 | 800 | |||||

| UMS45 | 12 000 | 385 | 4600 | 425 | 1.1 | 1.83 |

| UMS55 | 12 000 | 360 | 4000 | 550 | 0.7 | 1.91 |

Our sales department is ready to assist with selecting the optimum type of Tenax™ Filament Yarn. The values given in this table are guide values, obtained under controlled conditions by Teijin. For component design, please request a specification through our sales department.

The export or shipment of carbon fibers may be subject to authorization, depending on the properties, final destination, and end use. Each exporter is responsible for observing the regulations in their country. Additional import/export regulations from other countries may also apply.

Product Data Sheet

Cautions for purchasing Tenax™ Carbon Fiber

The carbon fiber filaments manufactured by Teijin Limited or its group companies (“Teijin”) are export-controlled item subject to the export control laws of the countries where the carbon fiber filaments manufacturing base are located as well as the export control laws of the country the carbon fiber filaments are sold from. The export controls are based on the agreements of the international export control regimes of the Nuclear Suppliers Group and the Wassenaar Arrangement on Export Controls for Conventional Arms and Dual-Use Goods and Technologies as well as country specific laws and regulations.

Therefore, when exporting its carbon fiber filaments, Teijin complies with the export control laws of the countries where the manufacturing base is located, and sells only to the customers and end-users and for end-uses permitted by the export control authorities of the relevant countries. Teijin does not sell any carbon fiber filaments on E-commerce (EC) sites operated by other than Teijin.

Please note that Teijin is not responsible for any export violations, warranty claims, losses, or damages with regard to the carbon fiber filaments purchased through EC sites operated by other than Teijin or any sales or distribution not authorized by Teijin.

If you are interested in purchasing Teijin carbon fiber filaments, please contact Teijin Limited or its group companies nearby.

If you have any questions about this matter, please contact us.