Dry Reinforcements

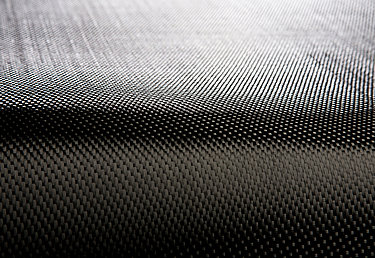

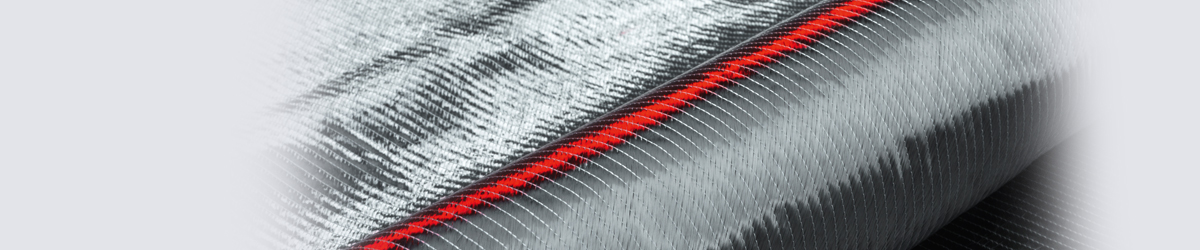

Tenax™ Dry Reinforcements provide high performance, flexibility, and the ability to create complex shapes. By combining textile technologies with resin infusion processes, dry reinforcement enables higher production rates, more integral structures, and flexibility in part design. Tenax™ Dry Reinforcements are the ideal base for the production of high-quality carbon fiber reinforced components.

The Tenax™ Dry Reinforcements product range

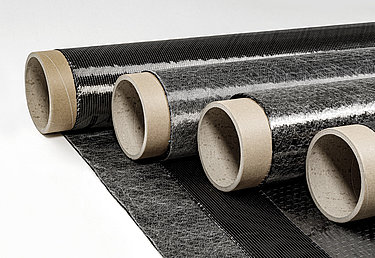

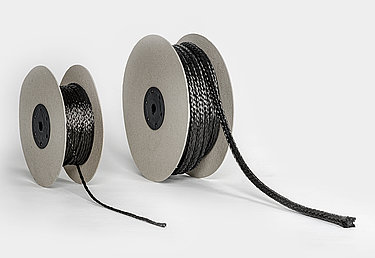

The Tenax™ Dry Reinforcements range of products provides a cost-competitive solution for a wide range of applications. The products meet current market standards and can be tailored to the specific needs of customers, such as class A surface requirements. They are also compatible with epoxy resins available on the market and can be combined as a package solution with Tenax™ Thermoset Resins (RTM and rapid cure). The product range includes Tenax™ Dry Reinforcement Non-Crimp Fabric (DRNF), Tenax™ Dry Reinforcement Woven Fabric (DRWF), and Tenax™ Dry Reinforcement Braided Fabric (DRBF).