Oil and Gas

Tenax™ carbon fiber provides high-performance solutions for oil and gas

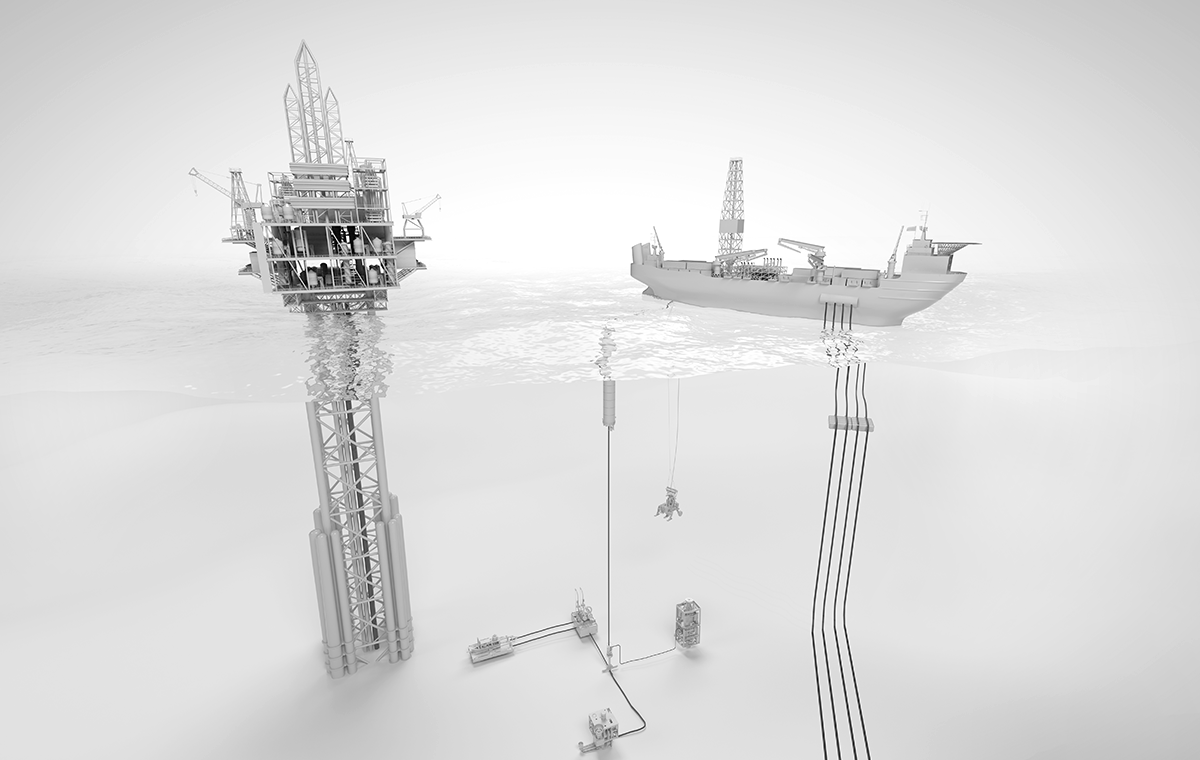

In the oil and gas industry, innovations in carbon fiber are driving the development of lightweight composite materials that replace steel and aluminum. The challenges of offshore drilling applications can be overcome by the properties of Tenax™ carbon fiber, which is strong, stiff, light, durable, and versatile, while also being fire, corrosion, and fatigue resistant. For deep and ultra-deepwater applications, Tenax™ carbon fiber from Teijin is a viable and cost-effective alternative to steel and other traditional materials.

Tenax™ carbon fiber helps oil and gas developers reach new depths

Tenax™ carbon fiber offers more stiffness and strength, with less weight, to enable deepwater exploration at depths that can’t be reached by traditional materials. Carbon fiber composite materials also reduce installation costs, installation times, and downtimes, while the extended product life cycles deliver improved product performance over longer periods of time.

Carbon fiber in the oil and gas industry

All Products

With unique properties such as high tenacity, high strength, and high tensile modulus, Tenax™ Carbon Fiber is ideally suited to reinforcing a wide range of deepwater products. When used as a replacement for steel, carbon fiber enables deepwater developers to reach new depths without compromising on strength.

Sustainable carbon fiber in the oil and gas industry

Teijin is innovating in carbon fiber not only with the focus on the future of the oil and gas industry, but also on the future of the planet. Products that are highly durable and reliable in extreme environments last longer and require less maintenance, helping to reduce waste.

Used Products :

Aerospace has always been an industry of technological revolution. Today, with the development of transport vehicles for space travel and the next generation of supersonic aircraft in development, the industry continues to drive innovation to new heights. (geklaut, umformulieren!!!)

In the aerospace sector lightweight is key and the global demand for thermoplastic materials is rising. These materials could take a leading role to sharply reduce the lifetime fuel consumption of an aircraft, to extend its flight range, to significantly reduce emissions and to prepare for recycling cycles of the future.

Carbon Fibre-Reinforced Thermoplastics (CFRTP) are often named in one breath with benefits like strength-to-weight ratio, durability, impact behaviour, series capabilities, sustainability and to lower the total cost of critical structures. Additionally to this unique performance the materials also deliver proven resistance to extreme conditions and environments.

Tenax™ Filament Yarn

Tenax™ Filament Yarn is increasingly being used in the oil and gas industry as a substitute for steel and aluminum, due to its strength-to-weight ratio, stiffness, durability, and resistance to corrosion. Applications include rigid and flexible risers, umbilicals, and monitoring rods. Tenax™ Filament Yarn can also be used for pumps, valves, and sealings.

Used Products :

Tenax™ Short Fibers

Tenax™ Short Fibers have high pressure, heat, chemical, and corrosion resistance, making them ideal for deepwater applications in the oil and gas industry. They can be used for components and parts, as well as for pumps, sealings, and valves.

Used Products :

Tenax™ ThermoPlastics

Tenax™ ThermoPlastics provide lower weight than steel and other metals, making them highly suitable to deepwater oil and gas applications. Their durability and strength also help to reduce installation time and costs. As carbon fiber thermoplastics are not susceptible to corrosion, they allow for a high flow rate in the riser due to the consistently smooth surface. They can also be used for components and parts, as well as for pumps, sealings, and valves.

Used Products :

Tenax™ ThermoSets

Tenax™ ThermoSets are designed to withstand the extreme conditions, environments, and temperatures of the oil and gas industry. Thermosets can be unidirectional, woven, and non-woven, and are used for integral structures, such as rigid risers.

Used Products :

Rigid risers

Carbon fiber is typically 20 times stronger than steel for the equivalent weight, making it an ideal material for reinforcing a rigid riser. Carbon Fiber filament winding provides reduced weight and increased pressure resistance for special offshore applications.

Used Products :

Flexible risers, choke and kill lines, jumpers and flow lines

Flexible risers and lines are the key connection between the seabed and the production system for the transfer of fluids. Tenax™ Carbon Fiber is used for the hybrid construction of risers, choke and kill lines, jumpers, and flow lines, by tape winding or with pultruded profiles. Carbon fibers are not susceptible to corrosion and enable a high flow rate in the riser due to the smooth surface.

Used Products :

Valves, pumps, sealings

Tenax™ Carbon Fiber can be used in valves, pumps and sealing systems that operate under high temperatures and high pressures, due to its outstanding resistance to corrosion, chemicals and fatigue.

Used Products :

Deep-water applications

Buoyancy products reinforced with Tenax™ Carbon Fiber short and milled fibers increase pressure resistance, provide enhanced strength, and help prevent the collapsing of the structure in deepwater applications.

Used Products :

Umbilicals and monitoring rods

Tenax™ Carbon Fiber is ideal for umbilicals and monitoring rods, to achieve higher tensile strengths with reduced weight. The rods can be made with smaller diameters, enabling access to wells with restricted diameters, while being corrosion resistant in extreme environments.

Used Products :

RTP - reinforced pipes

Reinforced thermoplastic pipes are flexible pipes used for transporting liquids and gases. When reinforced with Tenax™ Carbon Fiber, the pipes can withstand higher pressures and temperatures while being corrosion resistant. The pipes are used on land and also to transport hydrogen from offshore production facilities to land.